- YD

- China

- 10 days

- 100000 pcs

[product model]: universal accessories, we could supply all brands and models of Hydraulic breaker accumulator

[product material]: stainless steel

[customized products]: it can be customized based on the special size based on sample or detail drawing

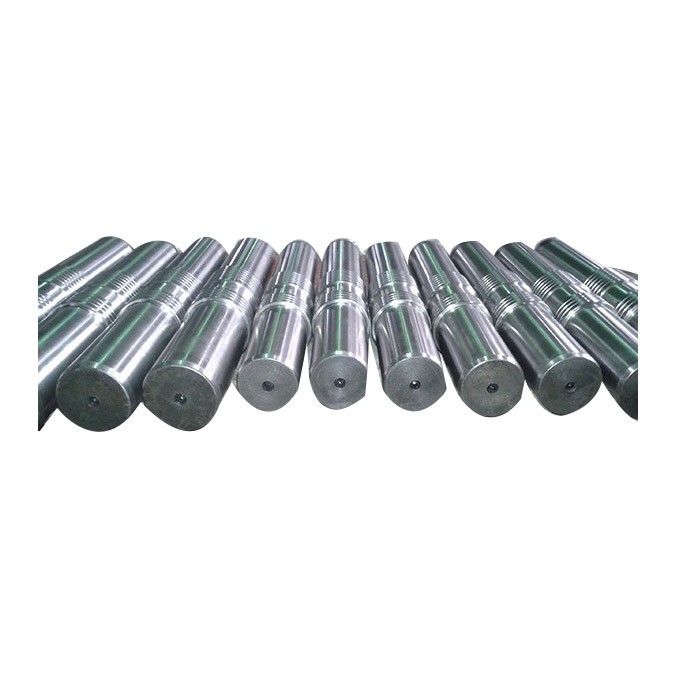

Piston

[product name]: hydraulic breaker hammer piston

[product brand]: ATLAS-COPCO、MONTABERT、STANLY、CHICAGO 、KRUPP、CAT 、KENT、NPK 、SOOSAN、JCB 、VOLVO 、FURUKAWA 、TOKU, etc.

[product model]: universal accessories, we could supply all brands and models of Hydraulic breaker accumulator

[product material]: stainless steel

[product size]: international common size

[product price]: factory outlet

[customized products]: it can be customized based on the special size based on sample or detail drawing

The reason why the breaker hammer is pulled

The crusher adopts the optimized design concept, increases the piston and cylinder stroke, and adopts the same large diameter of the piston and the drill rod, so that the matching effect between the breaker and the host is better, and the higher output energy is utilized reasonably, energy is saved, and the work efficiency is high. . Let's take a look at the reason why the breaker piston is pulled.

1. Improper repair method: Improper repair methods can not only cause strain on the piston and cylinder, but even cause more serious consequences.

2, the hydraulic oil is not clean: if the oil is mixed with impurities, these impurities are wedged into the gap between the piston and the cylinder, which can cause strain. This type of strain has the following characteristics: generally there are grooves with a depth of more than 0.1 mm, the number is small, and the length is approximately equal to the stroke of the piston.

3. Failure of the drill rod guide sleeve: the guide sleeve is poorly lubricated or the wear resistance of the guide sleeve is poor, and the wear of the guide sleeve is accelerated. The gap between the drill rod and the guide sleeve sometimes reaches 10 mm or more. At this time, the middle line of the drill rod is easily deflected. When the piston moves to the tail of the drill rod, the reaction force received by the piston is an eccentric force. A component of the force forms a radial force acting on the piston. The piston is biased to one side under the action of the radial force. The gap disappears, the oil film is destroyed, and dry friction is formed, which quickly strains the surface of the piston and the cylinder. The characteristic is that the tensile area is large, about 1/3 of the cylindrical area, and the trace of the strain is shorter, which is equal to the displacement of the drill rod.

4, the gap between the piston and the cylinder is too small: this situation often occurs when replacing the new piston, if the clearance is too small, the hydraulic hammer is working, the gap changes with the increase of the oil temperature, then the piston and The cylinder is easily damaged. It is characterized in that the tensile depth is shallow and the area is large, and its length is approximately equal to the stroke of the piston.

5. The hardness of the piston and the cylinder is low: the piston is subjected to external force during the movement. Due to the low hardness of the piston and the cylinder surface, it is easy to cause strain. Its characteristics are: shallow depth and large area.

Since the establishment of our company, we have been adhering to the management tenet of